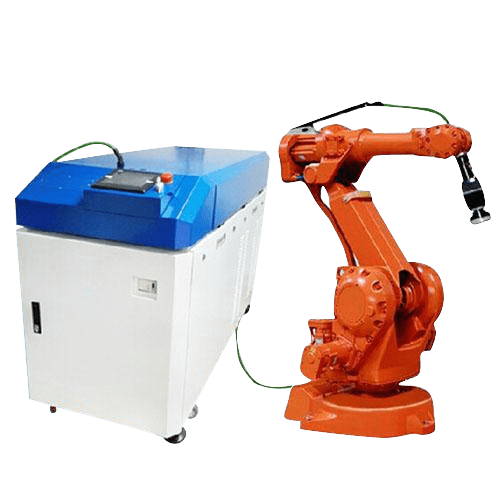

LASER WELDING MACHINE- ROBOT, HAND-HELD, AND MOLD WELDING

Share

The ROU-HJ series laser welding machine uses high-energy laser pulses to locally heat materials in small areas. The energy radiated by the laser is guided to the interior of the material through thermal conduction, and the material is melted to form a specific melt. It is a new type of welding method mainly aimed at the welding of thin materials and precision parts, which can achieve spot welding, butt welding, welding, sealing welding, etc. It has a high aspect ratio, small welding width, small heat affected zone, small deformation, fast welding speed, smooth and beautiful welding sugar, no or only simple processing after welding, high welding quality, no porosity, precise control, small focusing spot, high positioning accuracy, and easy automation.

Applicable scope

Electronics industry, jewelry industry, automotive and electric vehicle industry, energy lighting and building materials industry, battery industry. Mold welding is used for repairing various large and irregular mechanical parts such as cylinder tubes, pistons, crankshafts, rotor bearing positions, etc.

Benefits

1) Fast speed, deep depth, and minimal deformation

2) For example, when light passes through electromagnetic fields, it does not; Light can be used for welding in both air and certain gas environments, and can be welded through glass or materials that are transparent to the light beam.

3) Can weld refractory materials such as titanium, quartz, etc., and can also weld dissimilar materials with good results.

4) After laser focusing, the power density is high. When welding high-power devices, the aspect ratio can reach 5:1, and the highest can reach 10:1.

5) Micro welding can be performed. After focusing, the laser beam can obtain a very small spot and be accurately positioned, which can be applied to the assembly and welding of micro and small workpieces in large-scale automated production,